Our 3D laser scanners are ideal for capturing larger machinery and factory lines, as well as sites of cultural value.

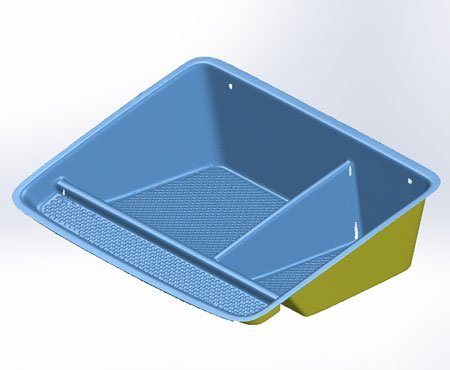

3D scanning for toolmaking

3D scanning for tool Makers

can we 3D scan your tool?

We offer 3D scans for tool-making. Do you need to to check for wear characteristics? Do you need to create a mould or a die? Do you need to analyse dimensions? By using 3D scanning technology you can create accurate 3d models, cutting out errors and streamlining the manufacturing process. You can see how mating parts fit together. You can design out any flaws or issues before the prototype is created.

We off an on-site 3D scanning service. Small components can be sent to us for in house 3D scanning. We can scan machinery, parts, tool, components and more. Get in touch to find out how we can help with your tool making project.

We also provide 3D scanning for bespoke jig manufacture.

3D scanning large objects

When 3D scanning large items we use our handheld mobile scanners. This type of scanner is suitable for objects from the size of a kettle up to the size of a vehicle. This type of scanner is mobile, so we can visit your site to carry out the 3D scan. It captures very fine details and it perfect for replicating larger objects.

3D scanning small objects

For smaller objects, we use desktop 3D scanners. They are perfect for smaller items and range from around 30mm up to roughly 350mm. These scanners are part of our in house service. Small items are mainly posted out to us. It works well for cogs, clips, jewellery and other small but detailed objects.

Get your 3D scan quote

Ready to streamline your toolmaking? Perhaps you need to reverse engineer, inspect or reproduce your parts. Our UK 3D scanning services offer highly detailed full-colour accurate scans. We also offer 3D printing services.

Recent 3D Scans

bumper

This is an unedited digital 3D scan of a ford front bumper. The holes on the bumper are from markers to aid with 3d scanning

The client wanted to use the data for several different reasons. The main aim was for fixing locations and modifications.

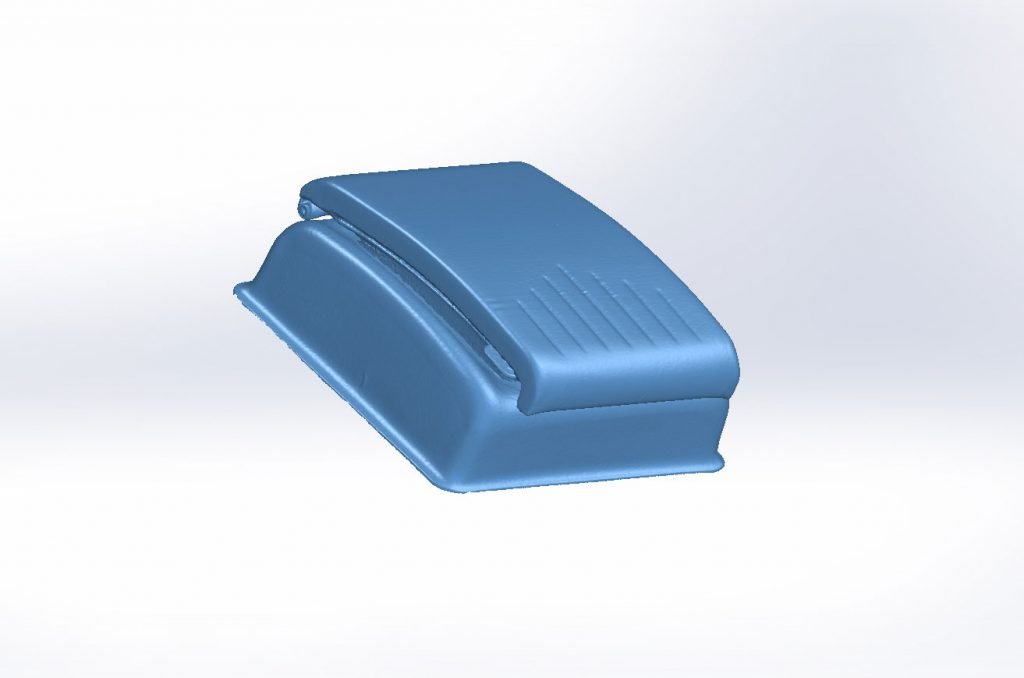

MG Ashtray

A customer took advantage of our 3d scanning services to create a mount for the cars main badge to fit to the ashtray. We 3d scanned the ashtray and the badge to capture the curves of both, and we then used our SLA 3d printers to create a mount to create what looked like an OEM badge mount.

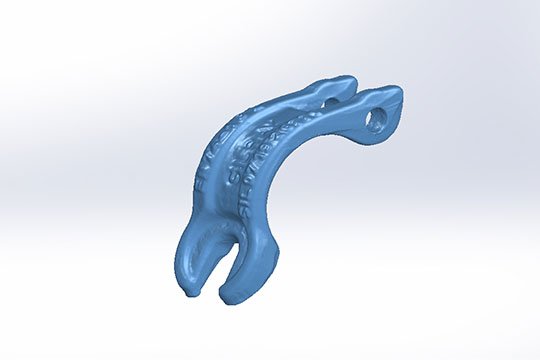

Chopper Frame

We used our mobile 3D scanning service for Raw Steel Choppers to digitally scan this rare chopper frame.

They were asked by one of their customers to reproduce the frame and make any modifications need and the data sent to a CNC company.

death penny

Here we used our desktop scanner for this world war one death penny. The customer wanted to reproduce the coin for so they could have their own copy. The coin was 3d Scanned with our desktop 3d scanner, we then cleaned the data ready for printing. The coin was 3d printed on one our resin printers.

Advantages of 3D Scanning

Saves time when designing products – If your product design is based on an existing object, then 3D scanning can capture every detail of the part. Providing you with the data to design a matching part that fits perfectly. Or if you are altering a current design, you can use our 3D scan data as a good starting point.

Simplify the prototype process – Our 3D scanning services can reduce the number of prototype cycles needed. You can also compare the 3D scan data between each version. The 3D Scan process will also highlight any design flaws.

Improved Quality Control – You can use the 3D scan data to check the quality of your product. You can also check the scale and stability of the product. It is perfect for the manufacturing process whether it’s 3D printing, CNC milling or injection moulding, you can spot deviations immediately and rectify them easily.

Re-manufacture parts without CAD Drawings – Want to re-manufacture parts but don’t have the original drawing? By using our 3D scanning services, you can create an exact drawing within hours. By reverse-engineering the scan data you can design a new product. You can then compare the drawing for the old and new products.

Keeping costs down – All of the above points save time during the designing, prototyping and manufacturing process. As we all know time is money. Utilising our 3D scanning services can make the design to manufacture process 75% faster, and therefore 75% cheaper!

Learn more about how 3D scanning works.

Already have your scan data? – If you already have your scan data but need it reversed engineered and maybe 3D printed, check out our other services.

Scan to CAD

Our 3D scanning service is ideal for CAD users. We can capture exact detail using our 3D scanners. Then transfer this data into a 3D solid CAD model. 3D scanning is a much faster and more accurate way to collect data. Saving you time and money.

If you work in CAD and want to measure an obsolete part this can be quite difficult. By using our 3D scanning services, we can create an accurate drawing within hours. This type of data is almost impossible to recreate by hand. We can provide you with accurate 3D scan data for a relatively low cost.

Lost CAD drawings are now a thing of the past. We can provide you with this information from a physical part. If you ready to find out more about our 3D scanning services to CAD, then please get in touch. We would like to hear about your Tool-making projects.

Often used by aerospace, furniture, and medical manufacturers.

Reverse Engineering

Our 3D scanning services and reverse engineering services work hand in hand. You can utilise the scan data to streamline the manufacturing process.

We will reverse engineer the data. You can design a part to fit on to the original part.

You can also redesign and improve upon the original object and remove design flaws from the original part.

Do you want to make your designing and manufacturing process more accurate and much simpler? Manufacturing better quality and more accurate parts? Then our 3D Scanning Services is the service you need.

If you would like to find out more, please get in touch to discuss your tool-making requirements.

Lets Talk

We’re ready for your enquiry. Please fill out the form, and someone will get back to you as soon as possible or give us a call, which ever suits you best.